Industrial productivity often suffers due to aging equipment, manual workflows, and lack of actionable insights. What’s missing? The intelligence to convert raw machine data into real-time, actionable insights that drive operational excellence.

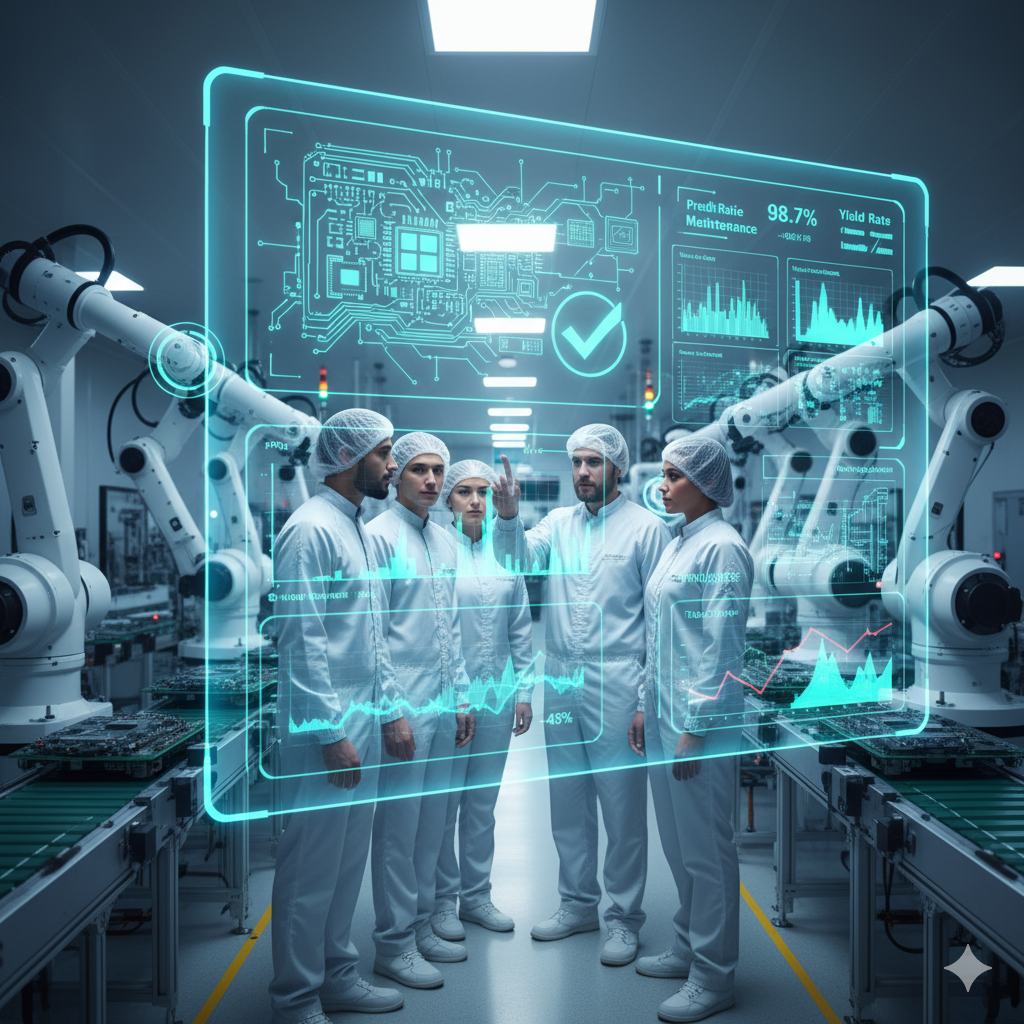

Move from manual, reactive operations to smart, measurable, and predictive manufacturing. Unlock efficiency, quality, and profitability with Evoluzn’s advanced Machine Data Digitization Solutions.

✔ Real-time equipment and environment monitoring reduces downtime and contamination risks.

✔ Enhances batch quality and supports strict regulatory compliance through data-driven process control.

✔ Precise machine-level insights minimize defects and boost yield in complex, technology-intensive lines.

✔ Predictive maintenance prevents unexpected failures, improving throughput and product quality.

✔ Live monitoring supports just-in-time manufacturing workflows, reducing rework on sensors, electronics, and battery components.

✔ Enhances production line visibility and quality control to meet demanding automotive standards.

✔ Ensures safe, high-yield battery production with precise equipment and environmental parameter monitoring.

✔Edge-enabled anomaly detection supports rapid predictive maintenance actions.

✔ TPM and OEE integration upgrades existing machinery for reduced downtime and material waste.

✔ Scalable solution provides clear operational visibility and quality assurance across production sites.